Tangential flow filtration (TFF) is a method of separation that uses a semi-permeable membrane to separate molecules or particles based on size, charge, or other properties. This technique is commonly used in the biotechnology and pharmaceutical industries to purify and concentrate biological molecules such as proteins, enzymes, and viruses.

The TFF process involves the use of a membrane filter that is placed in a housing unit, typically made of stainless steel or plastic. A liquid mixture is then introduced into the housing unit, and a pressurized pump is used to force the liquid through the membrane. The membrane acts as a sieve, allowing small molecules or particles to pass through while retaining larger molecules or particles.

One of the key advantages of TFF is its ability to handle high flow rates, which makes it an efficient method for large-scale purification. Additionally, TFF can be used to purify a wide range of biological molecules, including proteins, enzymes, viruses, and even cells.

Another advantage of TFF is that it can be used in a continuous or batch mode, depending on the application. In continuous mode, the liquid mixture is continuously fed into the housing unit, and the purified product is continuously collected. In batch mode, the liquid mixture is added to the housing unit in a single batch, and the purified product is collected once the process is complete.

TFF is also highly customizable and can be tailored to meet specific purification requirements. For example, by varying the pore size of the membrane, it is possible to selectively retain or exclude certain molecules or particles. Additionally, TFF can be combined with other separation methods, such as centrifugation or chromatography, to achieve even more specific purification results.

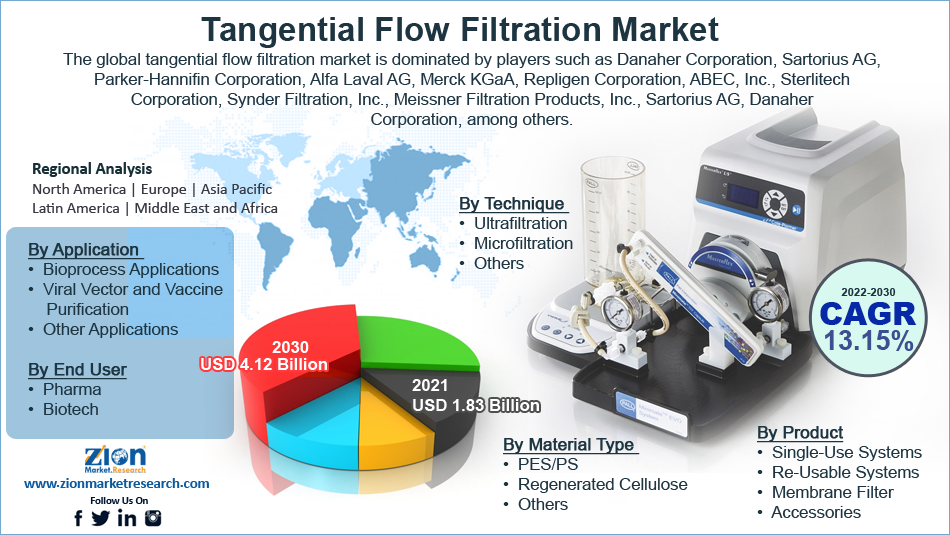

The tangential flow filtration market is driven by factors such as increasing demand for biopharmaceuticals, growth in the food and beverage industry, and rising awareness about water and wastewater treatment. Additionally, advancements in technology and the development of cost-effective and efficient tangential flow filtration systems are also driving the market growth. Government initiatives and regulations mandating the use of tangential flow filtration in various industries are also contributing to market growth..

The tangential flow filtration market (TFF) presents several opportunities for growth, including:

- Rising demand for TFF in the biopharmaceutical industry: TFF is widely used in the production of biopharmaceuticals, such as monoclonal antibodies, vaccines, and recombinant proteins, which are expected to drive market growth.

- Growing adoption of TFF in water treatment: The increasing demand for clean water and stringent regulations to control water pollution are expected to drive the adoption of TFF in the water treatment industry.

- Rising demand for TFF in the food and beverage industry: TFF is used to clarify, concentrate and sterilize food and beverage products, which is expected to drive market growth.

- Development of advanced TFF technologies: The development of advanced TFF technologies, such as ceramic membranes, is expected to create new opportunities for market growth.

- Growing demand in developing countries: The increasing demand for TFF in developing countries due to the growth in industrialization and urbanization is expected to create new opportunities for market growth.

- Increase in investment in R&D: Companies are investing in R&D to develop new TFF products and improve the existing ones, which is expected to drive the market growth.

In conclusion, TFF is a powerful and versatile separation technique that is widely used in the biotechnology and pharmaceutical industries to purify and concentrate biological molecules. Its ability to handle high flow rates, flexibility, and customizability make it a valuable tool for large-scale purification and downstream processing of biological molecules.###